The Production Scheduler application is intended for detailed operational scheduling of production. Enables manual entry or automatic retrieval of production orders, workflows and orders, BOMs, tool sheets and other necessary information from ERP. The retrieved information is displayed in the order management section of the application on a list of orders and individual operations, from which the scheduler assigns them to individual machines.

Production Scheduler

The time scheduling of jobs happens according to preset rules, as well as their rescheduling in the case of detected conflicts, which may include, for example, the unavailability of molds and tools for a given machine in a given time period.

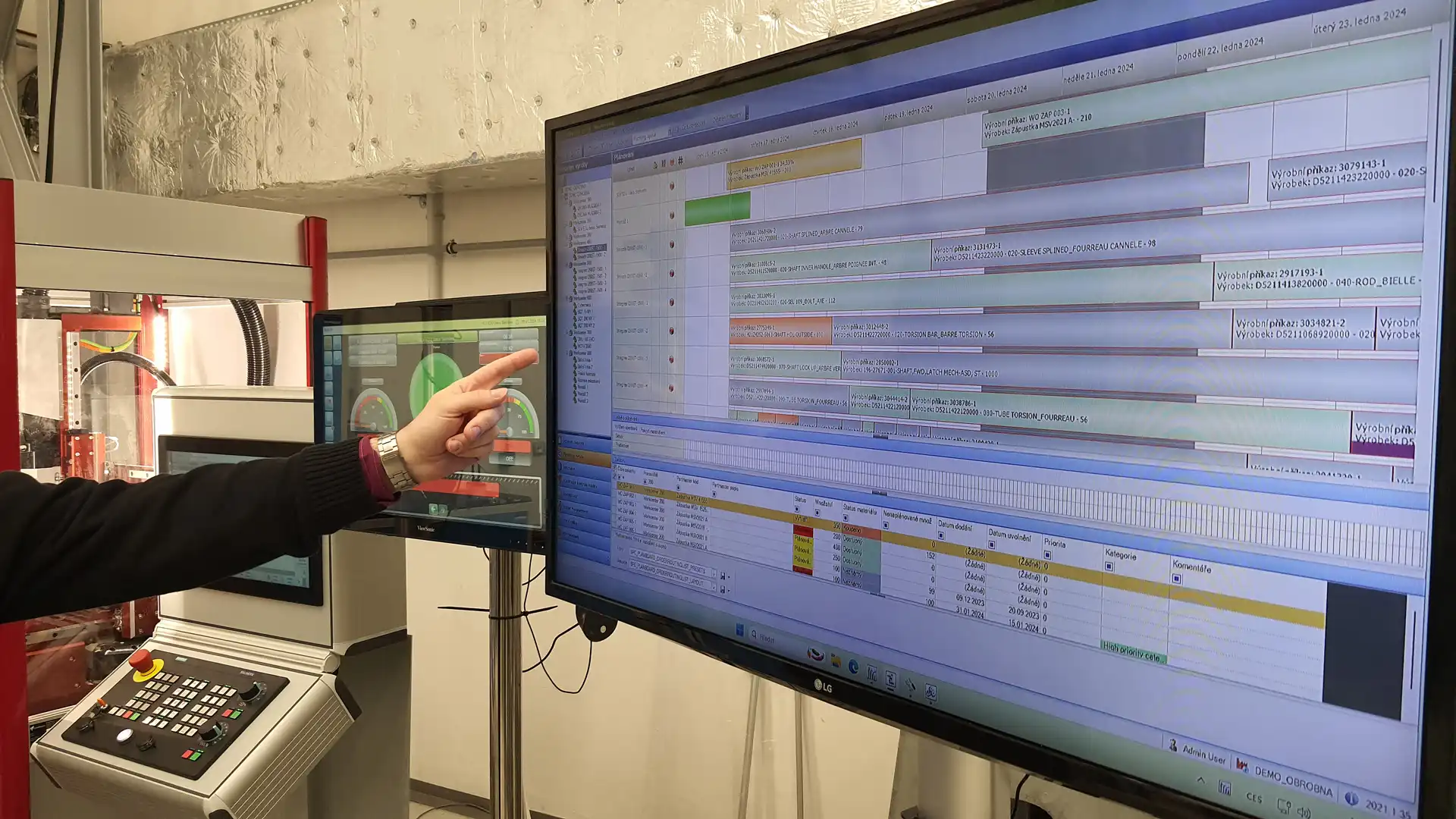

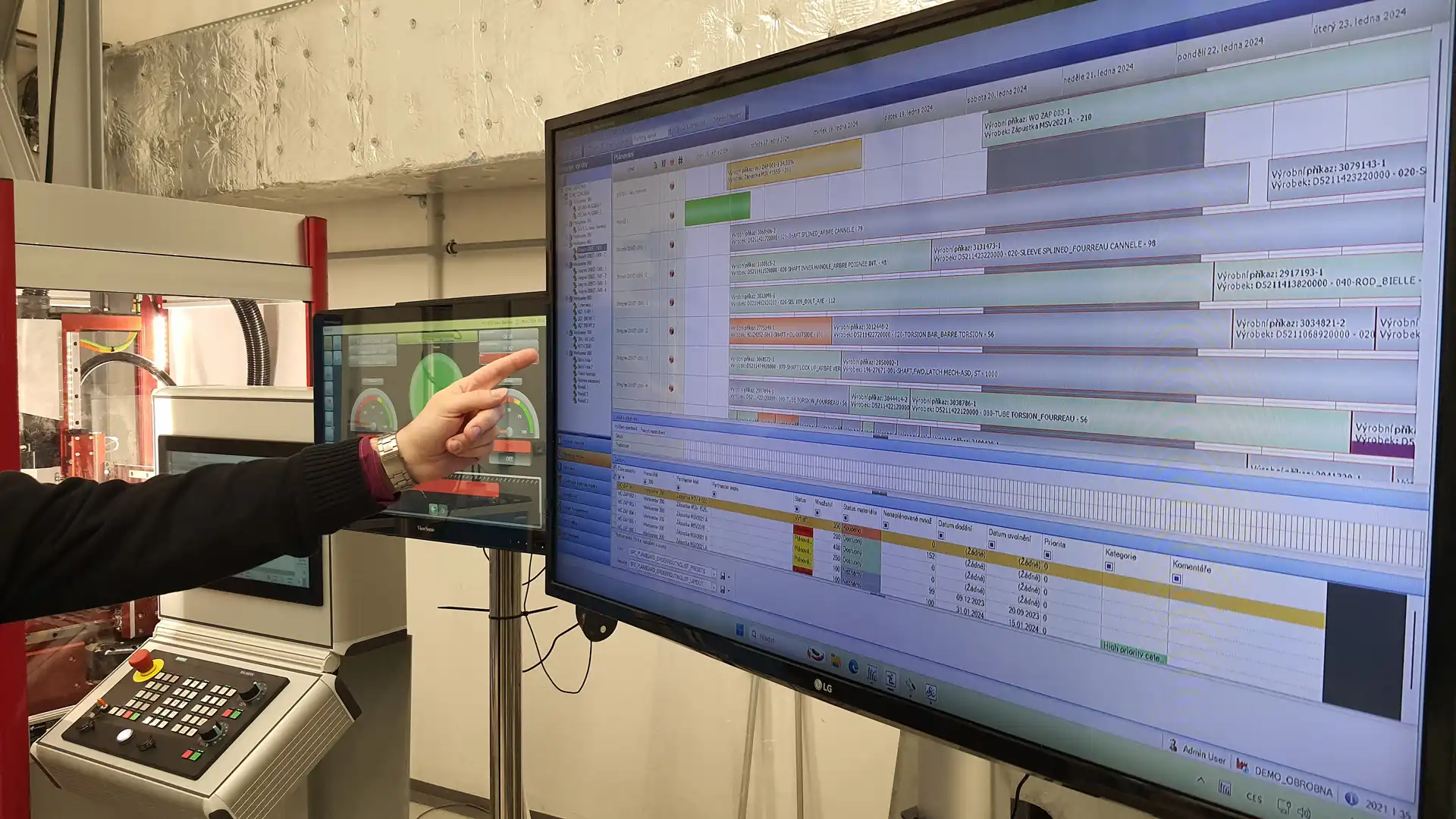

A very popular function is simple scheduling or rescheduling via drag & drop. Planned jobs are displayed to operators at the respective workplaces on production terminals with the application Field Client on which operators initiate and subsequently write off the respective jobs and operations. This information is automatically transferred and visualized on the schedule board in the Production Scheduler application.

The application also allows automatic connection to production machines, from which individual pieces and their production cycle time can be automatically calculated and this information can be projected online to the Production Scheduler, giving planners and foremen an up-to-date overview of schedule execution, individual job status and their operations, including the predicted date of their completion. Information on the status and deadlines of order fulfillment can then be automatically transmitted back to the parent ERP system.

The Production Scheduler application can work independently or can be linked with other Act-in applications such as ANDON, Field Client, Performance Analyser, Maintenance Control or Plant Monitor.