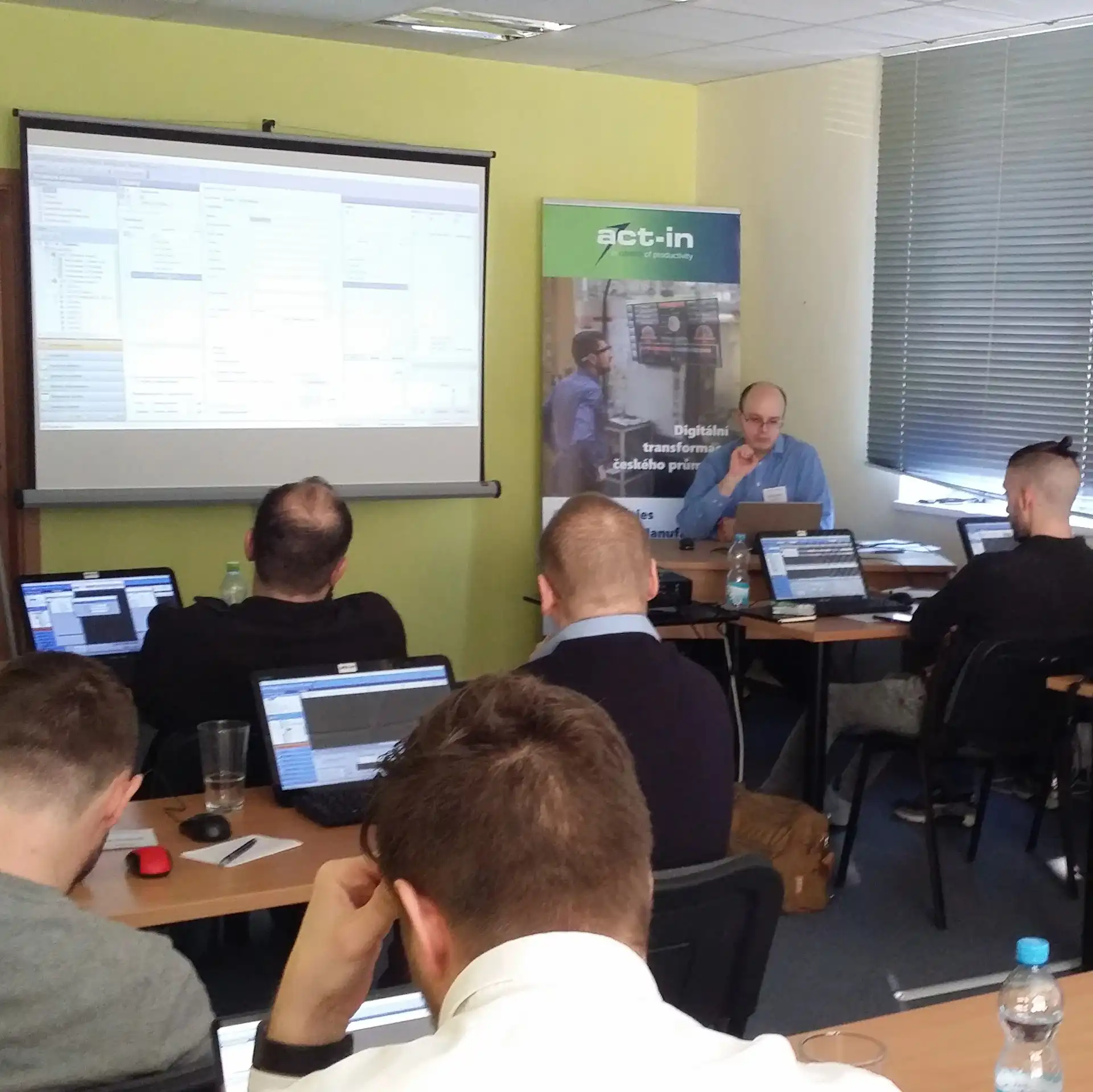

We also provide traditional professional training to help companies implement modern technologies, digitization and efficient industrial processes. For us, the TPM methodology represents a framework structure for covering a wide range of specific procedures and activities by which we help manufacturing plants to rationally optimize the care of their tangible production assets. TPM is a complex methodology, so it is important to devote sufficient time and effort to its training and implementation.

Training

Our activities focus mainly on the following areas:

- Autonomous maintenance

- Preventive maintenance

- Evaluating overall effectiveness (CEZ, OEE)

- Teamwork

- Selection of equipment according to its maintainability

- 5S

The starting point before starting a more complex cooperation can be an analysis of the current state or a maintenance audit, in which we mainly focus on:

- Company goals and strategies

- Derived maintenance department goals and strategies

- Established procedures, processes, responsibilities and authorities

- Assessment of the technical condition of production equipment

- Implementation of corrective, preventive and diagnostic maintenance

- Work planning and records of completed work

- Human Resource Management

- Spare parts warehouse management

- Supplier management

- Control of compliance with procedures

- Control of the fulfillment of objectives

- Computer support

Based on the findings, we subsequently propose specific action plans for further improvement and implementation of methodologies and procedures according to the customer's goals.